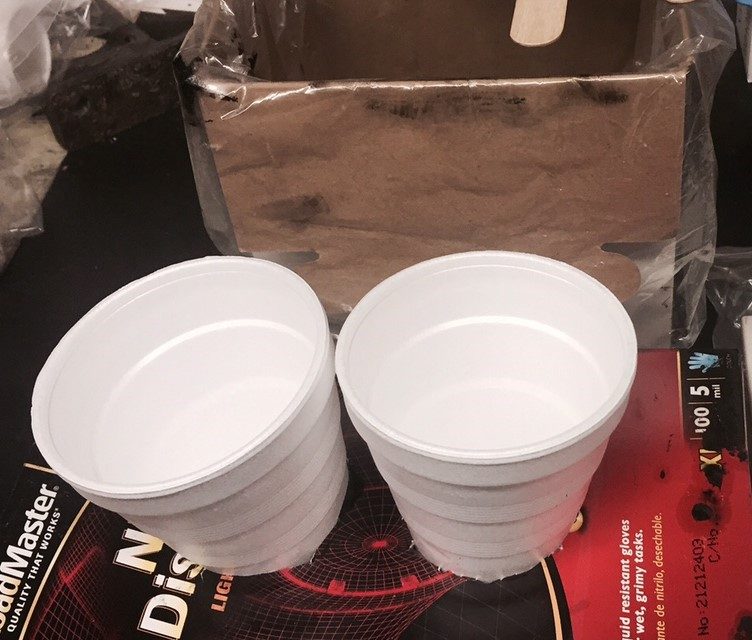

Applicators are constantly looking for easier ways to obtain a cup check, which most perform by themselves. The picture shown uses an empty box of Nitrile Gloves (PN20223) purchased on our webstore, with two holes cut into it by the sprayer after it was emptied. Great idea! This method helps to stabilize the cups, so they begin collecting Resin and ISO at the exact same moment. Low Pressure cup checks are essential for proper allocation of materials. The ratio data collected will immediately indicate which line is being starved of chemical, below or above the recommended amounts, the approximate 2:1 ratio should yield .58 – .63. It is highly suggested this test be completed once a day, if an application occurs the same day. *Always perform a cup check when you have opened a new set of chemicals.

*Ratio Problem?

.64 or higher. Resin side starved

.57 or lower. ISO side starved

There are other important items to remember while preparing materials for application. First, check all drum labels to verify the chemicals received are correct. Second, be sure to always agitate a newly opened drum on high the first time it is opened. After initial use, return to normal agitation speeds of medium to low, these speeds are based on drum levels. Agitating a drum with lower fluid levels on high speeds can add small air bubbles to the resin and effect the ratio and/or the products ability to cure properly. Remember, 1 minute of agitation per gallon of material. Lastly, un-pigmented Resin needs to be agitated before it can be transferred to a Q.C. tank or a smaller container for custom color pigmentation. All color jobs must be UV top coated!

Don’t hesitate to apply colored liners. It’s very simple, if you follow our recommendations and contact us. Value added services are necessary to grow your business. For technical questions please contact 858-450-0441 ext. 2